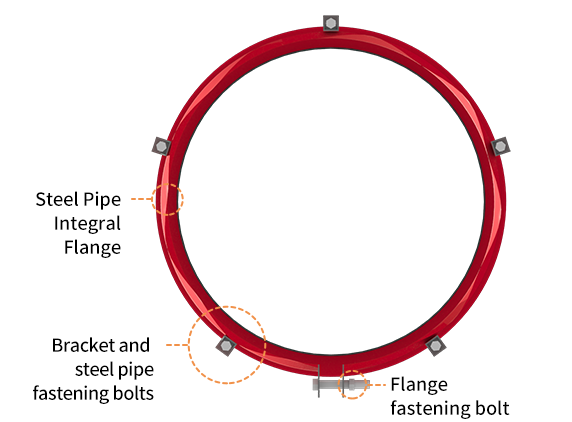

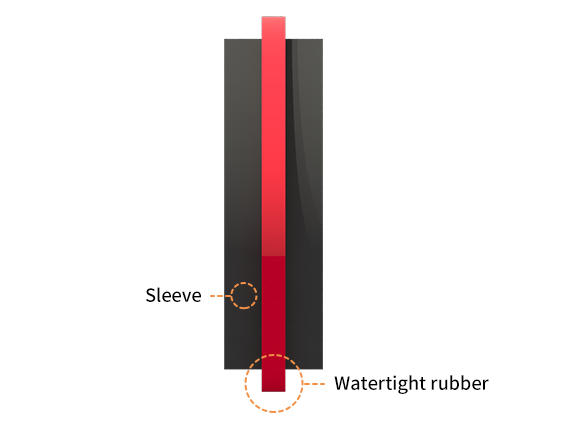

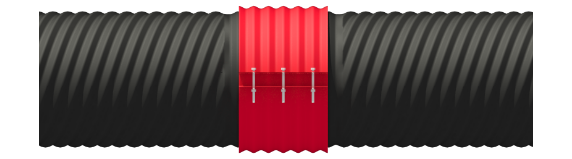

Coupling band

It is a most commonly used and highly-constructable joining device that places a watertight gasket around the outer surface end of recorrugated steel pipe and covers it with a coupling band by bolt-joining

-

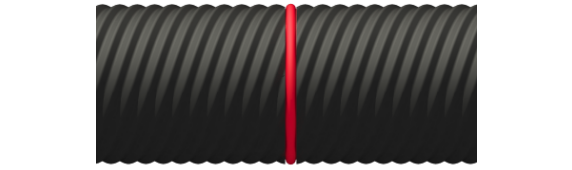

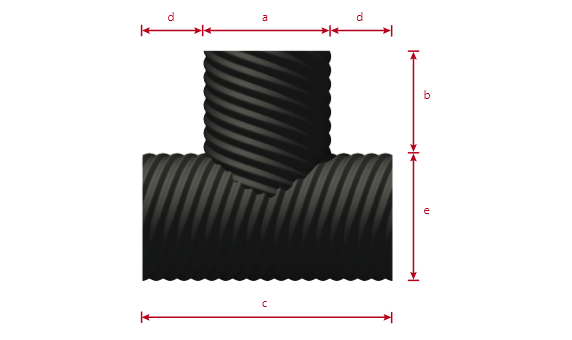

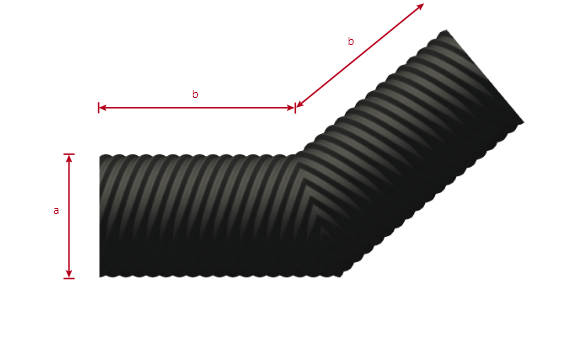

Corrugated steel pipe layout

Corrugated steel pipe layout -

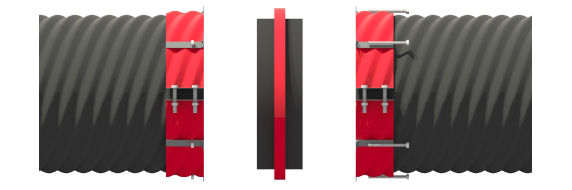

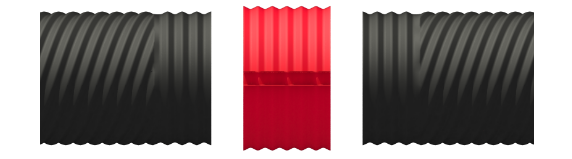

Coupling band joining

Coupling band joining