-

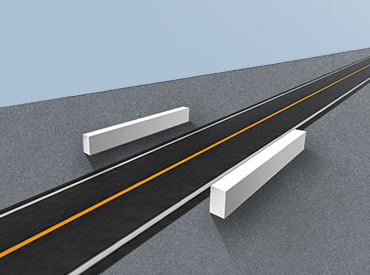

01. Excavation, foundation and base channel installation

-

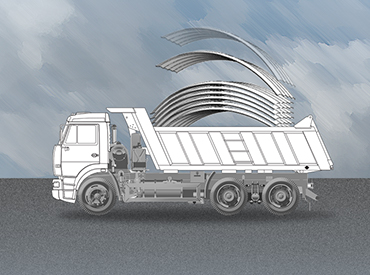

02. Transport of corrugated steel plates

-

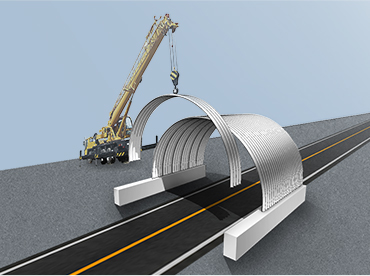

03. Assembly of corrugated steel plates

-

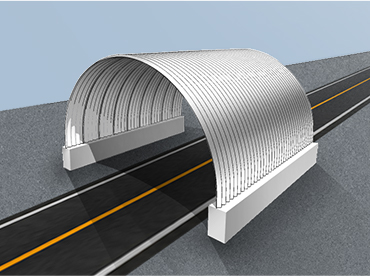

04. Assembly complete

-

05. Backfilling and compaction

-

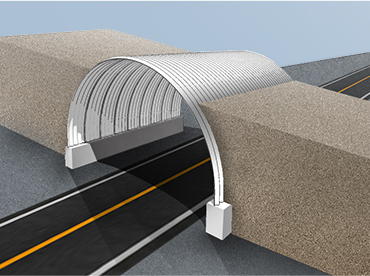

06. Construction complete

Construction Process

Considerations for construction

| Prepare on-site construction |

|

||||||

|---|---|---|---|---|---|---|---|

| Material inspection |

|

||||||

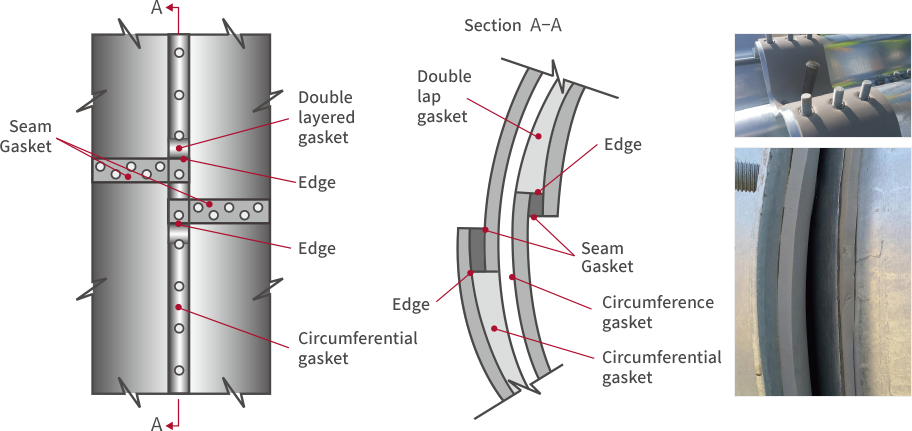

| Joint waterproofing and back drainage |

|

||||||

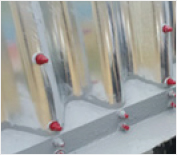

| Primary gasket waterproofing |

|

||||||

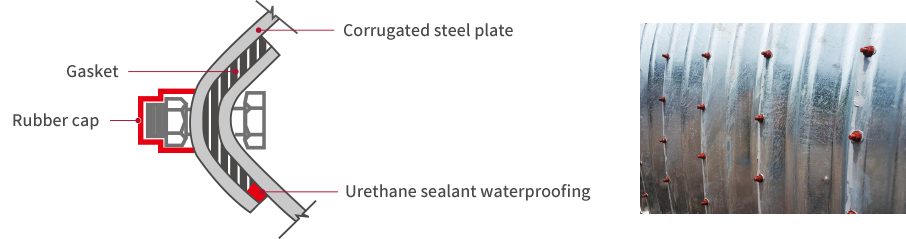

| Secondary urethane sealant and rubber cap waterproofing |

|

||||||

| Schematic diagram of secondary waterproofing for overlapping parts |

|

||||||

| Sectional displacement measurement |

|

||||||

| Tolerance level of structural deformation during and after construction |

|

||||||

| Sectional displacement measurement |

|

||||||

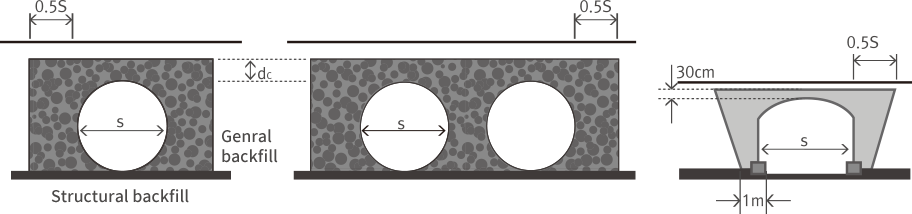

When installing an underground steel plate structure in the fill area

|

|||||||

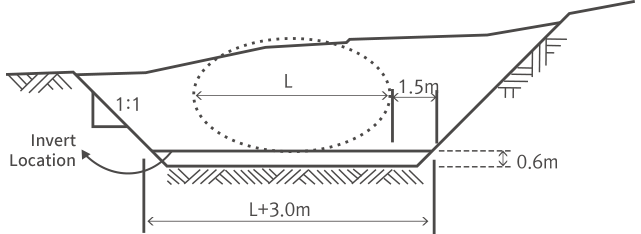

When installing after excavating the foundation ground

|